Construction of a new motorway in Serbia is bringing more than just transport connectivity to the region. It is also bringing communications improvements and flood resilience.

Opening of the first section of the Morava Motorway in Serbia this spring has given the local community a glimpse of the benefits that will come in 2025 when the whole 109km dual carriageway opens.

The design and build joint venture of Bechtel and Turkey’s Enka (BEJV) overcame significant supply challenges to open the first sections in April by bringing materials supply in house.

Opening the rest on programme will also mean bringing more operations in house, including the opening of a second major quarry to serve the project.

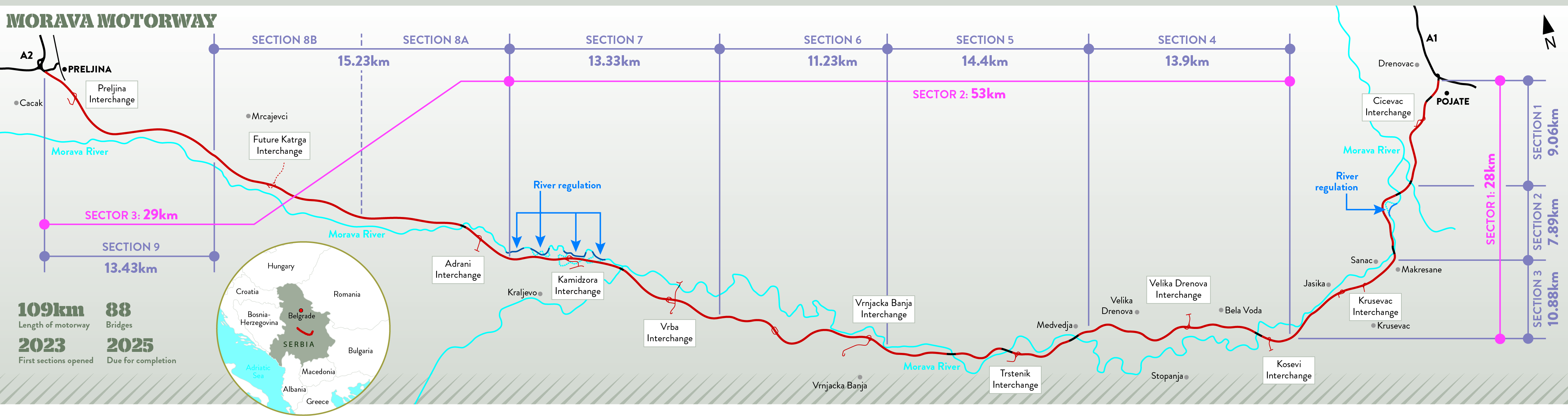

The new motorway, about 200km south of the capital Belgrade, runs east to west across Serbia between Preljina in the east and Pojate in the west, connecting the existing north-south A1 and A2 motorways. The east-west route will also create better transport links with Hungary and North Macedonia and bring investment to the region with three new government-planned industrial zones.

BEJV’s work for Serbia’s Ministry of Construction, Transport & Infrastructure also involves river regulation work to protect the new motorway from flooding and improve resilience for the local communities (see box). Connection improvements to be delivered by the route go beyond transport, with telecoms ducting for 5G fibre optic infrastructure being built into the new road to serve the region.

Funding for the project has come from UK Export Finance, the World Bank and the Serbian Government, although BEJV project manager Vick Nayson says the full cost of the project has not yet been made public.

Nayson expects to have the full figure confirmed by the government in October. Nonetheless, once completed in 2025, the cost of construction will be paid for by tolls.

The project is clearly an important one for the Serbian Government in terms of economic growth but it is also a major scheme for Bechtel and Enka, which have been working together on projects in the Balkan states for several decades. It is the largest scheme to be delivered by joint venture in the region to date.

That local experience led the Serbian Government to award the contract directly to BEJV without a tender in early 2020, although the firms first started discussing the project in 2017.

Although it is larger than the other schemes previously delivered by BEJV, Nayson says the river regulation work is what makes the scheme unique.

Even though construction of the river regulation element is still underway, the work delivered so far has proved its worth as two severe floods had no impact on the opening of the first sections in April. Floods only caused small delays to construction elsewhere, despite causing the collapse of an existing bridge close to route.

A job of three parts

The 109km route is split into three sectors, with each divided into sections. Sector 1 comprises sections 1 to 3 and runs 27.8km from Pojate to Kruševac. Sector 2 includes sections 4 to 7 and is the longest sector at 52.9km, running from Kruševac to Adrani. Sector 3, which includes sections 8 and 9, is 28.7km long and connects Adrani to Preljina.

BEJV will actually construct 112km of road in total, but 3km built for Sector 1 will not be used following a change in the starting point of the motorway.

As with many projects, Covid had an impact on the work. The Morava Motorway scheme was still in the early stages of moving onto site when the pandemic hit so it prevented the work from ramping up in the way that had been planned. Nayson implemented a project-wide vaccination programme in early 2021, allowing staff numbers to rise rapidly from 310 people in March 2021 to 3,800 today.

Given the challenges at the start of the construction phase, getting the first two sections of motorway open in three years and just after winter is seen as a major achievement by the project team and the Serbian Government.

Key to that early spring opening was BEJV’s self-sufficiency. It has its own quarry, an onsite concrete precasting yard and dedicated asphalt and concrete plants.

The JV also set up its own supply of polymer modified bitumen (PMB) binder for the asphalt. In addition it used a new bitumen additive for the Serbian market – Interflow T – that allowed the project to lay asphalt paving through the winter months.

A dedicated bitumen and asphalt plant was set up

According to BEJV engineering manager Erdogan Kilic, the additive had previously been used by the joint venture to good effect on another motorway project it had worked on in Kosovo. Nonetheless, Kilic’s team had to prove to the Serbian authorities that it was suitable.

“Supplies of PMB are unavailable here in the winter, so we had to set up our own plant,” adds Kilic.

“White lining in winter was also a challenge as the surface has to be above a specific temperature and we had to use surface heaters in order to do the work in winter.”

With 88 bridges – the longest of which is 717m long, while the shortest is just 7m – and 10,000 manholes planned for the whole 109km route, construction of concrete structures is a key part of the work and a decision to establish two precast concrete yards close to the alignment was taken early.

Operation of the yard near Sector 1, which had 200 people on site at peak, is now winding down while the one at Sector 3 is just starting to ramp up.

In addition to casting the pre-stressed U, I or T beams for the bridges, the yards are also casting four types of manhole and 1M scour protection tiles for the project.

BEJV civil engineer superintendent David Hanna says: “Precasting the structures has allowed us to ensure quality control and has made assembly on site more modular and less affected by wet weather than casting insitu would have done.”

The casting yards are also steam curing the beams to allow the concrete to achieve a high early strength – usually 70% in 11 hours – and maximise production capacity.

The beams vary in length from 14.4m to 38m. They are labelled with their final destination straight after casting and stored on site until just before they are installed. Hanna says the post-tensioning is undertaken a maximum of two weeks before installation.

Current construction focus

With sections 1 and 2 in Sector 1 now open, work on section 3 is progressing. This is quite different to the earlier work, which was completely offline.

Section 3 involves complex traffic management as it is an upgrade of an existing route. Here road users will get an early look at the new road as traffic is diverted onto it to allow the existing single carriageway and bridges to be rebuilt to the new standard.

Hanna says the use of precast concrete structures is particularly essential here as it allows overbridge construction to be completed with only brief road closures, as well as ensuring the programme for the bridge rebuilds is predictable.

Two precast yards were set up on the route for the project

Construction of Sectors 2 and 3 is also progressing and each of the sections within those has its own technical challenges.

Sections 4, 5 and 6 in Sector 2 are greenfield sites and earthworks are well underway. BEJV estimated at the start of the project that, despite the relatively level alignment, it would involve the excavation of 48M.m3 of material.

Nayson says the two longest bridges on the scheme – 700m long each – will be constructed in sections 4 and 5.

But Section 7, the final part of Sector 2, is where the major challenges lie. Waste from magnesium production has been buried on the alignment and, while not contaminated, its geotechnical properties are unsuitable for road construction. The material will have to be dug out and replaced.

The biggest of the utility challenges also lies in section 7. The whole project requires the diversion of around 500 utilities with 30% completed so far.

Above section 7 are 5km of 132kV cables carried on pylons. Nayson says that these will be buried as part of the diversion but that work will take another one or two years due to the need to obtain the necessary consents.

In section 7, a 500m section of railway also has to be diverted to make way for the motorway.

The design of the diversion, which includes a railway bridge, is currently awaiting regulatory approval and when it comes, BEJV will have to subcontract the work because it does not have the necessary permits to undertake rail projects in Serbia.

“These technical issues mean that Sector 2 will be the last part of the route to open,” says Nayson.

Sector 3’s two sections are a mix of greenfield and brownfield land but the challenges here are less technical and more materials related.

The Plana Quarry has supplied rock for the river work

“We will need to open another quarry to complete the project,” says Nayson. “We identified 54 site options and have it down to one now, but it is remotely located and we will need to build an access road to avoid sensitive locations on the existing local roads.”

The existing Plana Quarry to the east of Pojate was opened specifically to serve the project. It has supplied limestone – mostly for river regulation work – at a rate of up to 50,000t a week.

Nayson says that only 4,000t a week was available locally and BEJV also had to buy in the igneous material needed for the asphalt on Sector 1.

Nonetheless, the quantity of aggregate needed for asphalt in Sector 3 and later Sector 2 is unavailable and current supplies will only allow completion up to section 5.

“Securing the quarry is the main risk to opening the whole project in 2025,” says Nayson.

But he believes the issue of the quarry will be resolved soon.

Beyond the technical and materials challenges, Nayson’s only other concern is the weather and he hopes that this year’s floods are not repeated on the same scale during the rest of the construction phase.

Community and environmental demands

Involvement of the World Bank and UK Government funding, along with delivery of the work by international contractors like Bechtel and Enka means that the project is being delivered to international standards.

While the UK may take community relations officers as a given, it is a new approach in Serbia. It is one that has been well received and is considered essential due to the large number of landowners and tenant farmers on the route.

According to BEJV community relations officer for Sector 2 Jasmina Vucic, farmers have been compensated for the land taken by the project but they are still farming alongside the construction work. She adds that the project has brought alternative employment for many people in the region, including herself as she lives in Kruševac.

More than 40% of the workforce on the project has been hired from the local community.

Vucic’s counterpart on Sector 1, Hristina Gvozdenovic, also grew up in the Kruševac area and is proud to be working on the scheme. She adds that knowing the area well helps with her role.

New environmental standards are also being set on the project. Tasked with ensuring that those are adhered to and that the project delivers a positive net biodiversity gain is BEJV environmental lead Sinem Aksit.

She emphasises that these standards are not aspirational but are essential to securing each tranche of World Bank funding.

River regulation

Most of the 109km route of the new Morava Motorway benefits from flat, level ground but the downside to the topography is that it lies almost wholly within the flood plain of the Morava River. Nayson describes construction of the route as “dancing with the river”.

River regulation work is an essential part of the road project

BEJV river regulation superintendent Kevin Crandall says: “The river level can go from low water to high water [flood conditions] in a matter of hours. The level isn’t just affected by heavy rainfall, there are three major dams upstream and when those reach capacity, the excess adds to the flow.”

The region was affected by severe flooding in 2014 and the flood experienced in May this year reached similar levels, underlining the need to protect the new road infrastructure from flood risk.

However, the river regulation work goes beyond the needs of the motorway as it will also reduce flood risk for some local communities.

“We are using four methods of river regulation to protect the motorway against one in 100 year floods,” explains Crandall.

“To protect against erosion of motorway structures or riverbanks close to the motorway, we’re using either riprap [quarried rock placed over the slope] or precast concrete slope protection tiles. Dykes are being built in some areas to increase flood protection. In others we are relocating the river channel, generally where the river bends towards the motorway. For the new bridges, we are constructing scour protection within the river around the piers.”

Crandall’s work on Sector 1 involves protecting four structures, constructing a 7.4km length of earth embankment dyke and relocating a 2km section of the river channel. He estimates that the work was 60% complete when NCE visited the site in late July.

Sector 2 will involve protecting more structures and the construction of a 12km long dyke. Work on that is just getting underway.

Sector 3 that poses the main challenges due to the scale of the work needed there. Crandall says that the knowledge gained on Sector 1 – and confidence from the work having withstood the spring floods – will be invaluable. For Sector 3, Crandall’s team will relocate 25km of river at 15 locations and will install riprap at 10 locations. Work there has already started and about 20% has been completed so far.

“Sectors 2 and 3 also contain the largest bridges on the route with more piers in the river that will need scour protection,” Crandall adds. “At first glance, you might think that the river regulation is 35 times what it needs to be here, but the floods this spring proved otherwise.”

Like what you've read? To receive New Civil Engineer's daily and weekly newsletters click here.

New Civil Engineer Civil engineering and construction news and jobs from New Civil Engineer

New Civil Engineer Civil engineering and construction news and jobs from New Civil Engineer

Have your say

or a new account to join the discussion.